Introduction TO MS Series Measuring System

Combininghigh magnification of metallurgical microscope with 3 axises measurement ofimage measuring instrument,MS measuring microscope is available forbright&dark field,DIC, polarizing observation, and is widely applied forindustrial inspection, such as semiconductor, PCB, LCD, hand phone, opticalcommunication, basic electronics, mold hardware, automobile and so on.

● Outstanding optical technology forexcellent imaging

Professional and advanced technology isessential to research and development. Superior infinity optical system,working with semi apochromatic objectives, presents a sharp image with highcontrast and clarity. With simple accessories, different performance such asdark field, polarizing, DIC is available.

● Ergonomics design realizes the comfortableoperation

Working efficiency and speed are mainlyeffected by the tool operability. All design based on ergonomics, reduces thefatigue caused by hard work. Welcome to experience MS measuring system.

● Precisionmeasurement ensures data accuracy

Good measuringtool represents a brand value. With the development of manufacturing technologyfor miniaturization and precision, high accurate measurement is more and moreimportant. MS series adopts 3 axises measuring system with 0.1um precision. X/Yaxises manual operation and Z axis electric focusing with high accurate gratingscales, is easy for operate without fatigue.

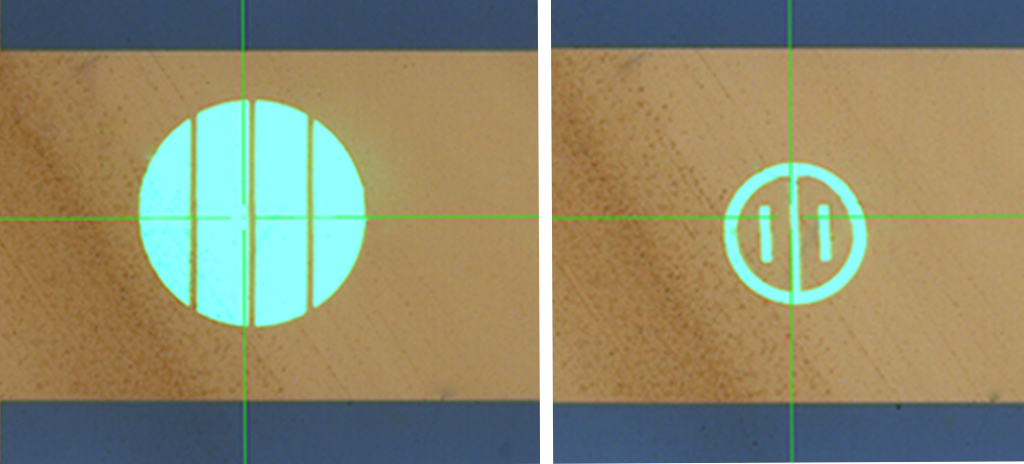

● Independentfocus assist of split image

The lightcontroller of split image is independent. Light intensity is able to beadjusted according to different samples. Two patterns of split image foroption, support for free switch.

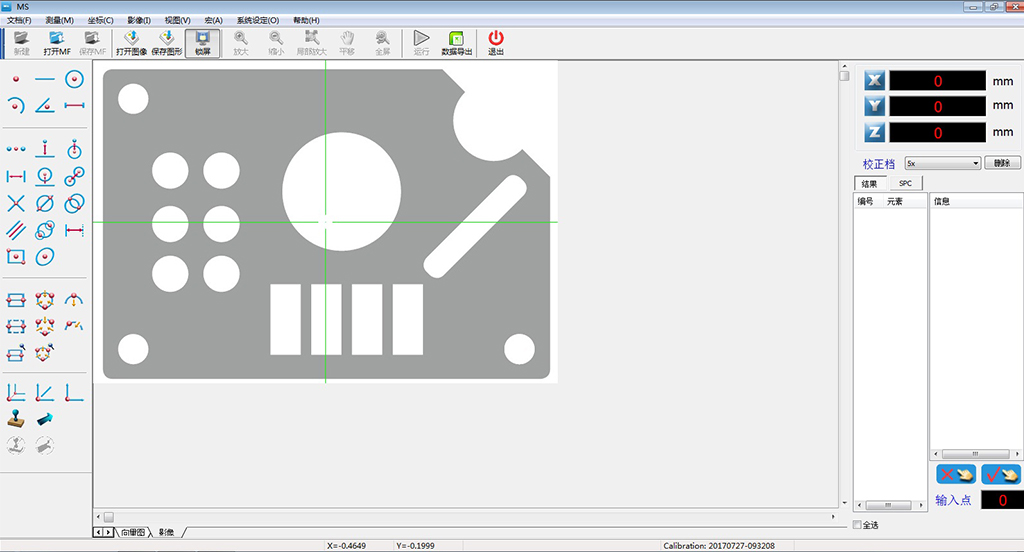

● Self-designed measuring software

It is availableto set up the customer preference by the powerful software. High-precisionmeasurement is achievable for the complicated shapes.

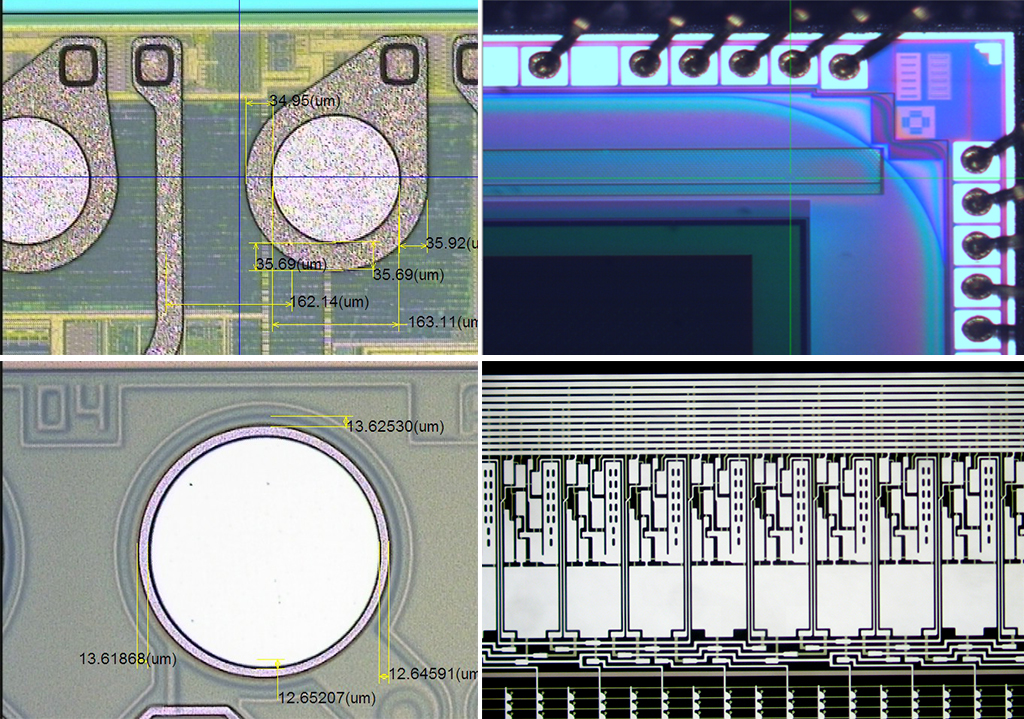

● Applicationcase

Technical specifications

Optical system | Infinity optical system |

Viewing head | 30 degree inclined trinocular head (erect image); interpupillary distance: 50~76mm; splitting ratio: 100:0 or 0:100. |

5~35 degree tilting trinocular head (erect image); interpupillary distance: 50-76mm; splitting ratio: 100:0 or 0:100. | |

30 degree trinocular head (inverted image); interpupillary distance: 50-76mm; splitting ratio: 100:0 or 50:50. | |

Eyepiece | High eye point wide field plan eyepiece PL10X/22mm, reticle attachable. |

High eye point wide field plan eyepiece PL10X/22mm, with adjustable diopter, reticle attachable. | |

Nosepiece | Quintuple nosepiece |

BD quintuple nosepiece | |

Objective | Long working distance plan achromatic metallurgical DIC objective 5X/10X. |

Super long working distance plan semi apochromatic metallurgical DIC objective 20X. | |

Long working distance plan achromatic metallurgical objective 50X/100X. | |

Long working distance BD plan achromatic metallurgical DIC objective 5X/10X. | |

Super long working distance BD plan semi apochromatic metallurgical DIC objective 20X. | |

Long working distance BD plan achromatic metallurgical objective 50X/100X. | |

Magnification | Optical magnification: 50X~1000X |

System magnification: 135X~2700X | |

Stage | Manual stage, moving range: 200mm(X) x 100mm(Y), measuring precision: X/Y (2+L/200)um, Z (3+L/200)um; with digitalindicator and control box for electric focusing; support for 175mm as the highest. |

Manual stage, moving range: 300mm(X) x 200mm(Y), measuring precision: X/Y (2+L/200)um, Z (3+L/200)um; with digital indicator and control box for electric focusing; support for 175mm as the highest. | |

Illumination | Reflected illuminator with shifter for bright and dark field; with slots for filters and polarizing kit; 5W LED (green),intensity adjustable. |

Focus assist, with double reticle; 5W LED (green), 100V-240V | |

Focus | Electric hand wheel, focusing distance: 175mm |

Camera | Color CMOS camera, 1.3 mega pixels, 1280 (H) x 1024 (V); 30fps; USB2.0 |

Adapter | 0.65X C-mount adapter |

0.5X C-mount adapter | |

PC | LENOVO Think Centre |

Software | Measuring software |

Accessory | Polarizer, 360 degree rotatable analyzer, interference filters, high precision micrometer, DIC, calibrater |