IMEXTWRH is a tailor-made product that is specifically designed to measure thesurface roughness of steel wire. IMEXT WRH is based on a powerful imageprocessing and analysis platform that combines image acquisition, imageprocessing, measurement and analysis, and customizable reporting to greatlyimprove work efficiency. Embedded advanced features: EFI, MIA, 3D surfacedisplay, scratch removal, automatic particle edge finding and more.

Supportswire thickness measurement while built-in layer depth measurement, phasecontent analysis, particle and pore analysis software package.

IMEXTWRH is mainly used for the inspection of wafer cutting lines in thesemiconductor industry, and is also suitable for roughness measurement of steelwires.

1、Software and hardware integrationsystem

Thesystem is an integrated image system with functions of image acquisition, imageprocessing, automatic identification and measurement, analysis and statistics,automatic generation of reports, and peripheral hardware control.

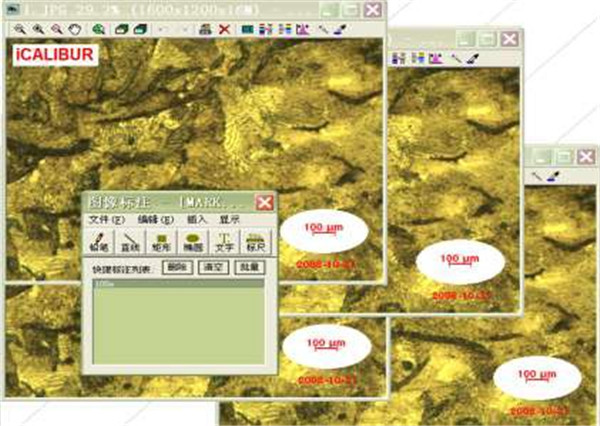

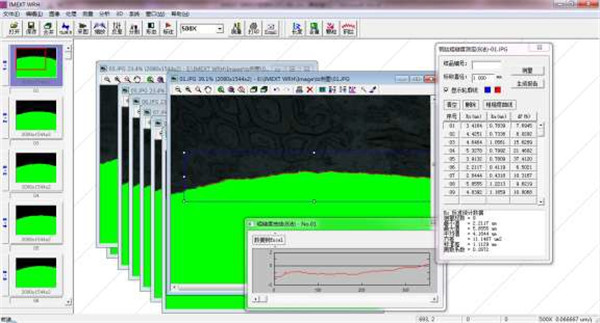

2、Batch image acquisition archive

Realizethe process of "real-time preview, fast capture, superimposed ruler,information annotation, identification measurement, analysis and statistics,save archive" inspection process; provide multi-image batch processingfunctions such as batch photographing, batch labeling, batch saving, batchconsolidation, etc. The process is more convenient and efficient.

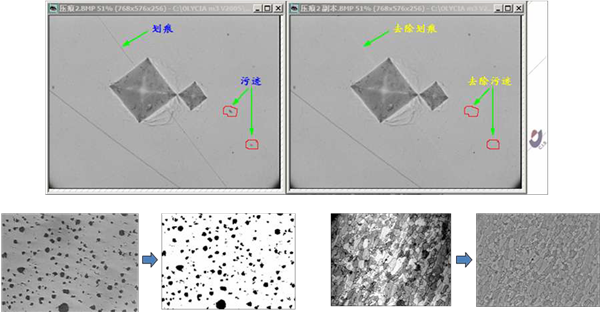

3、Powerful image processing andimage correction

Imageenhancement, contrast adjustment, color separation, multi-channel colorsynthesis, image correction, scratch smear processing; image annotation, layermerging, image database; convenient ruler tool.

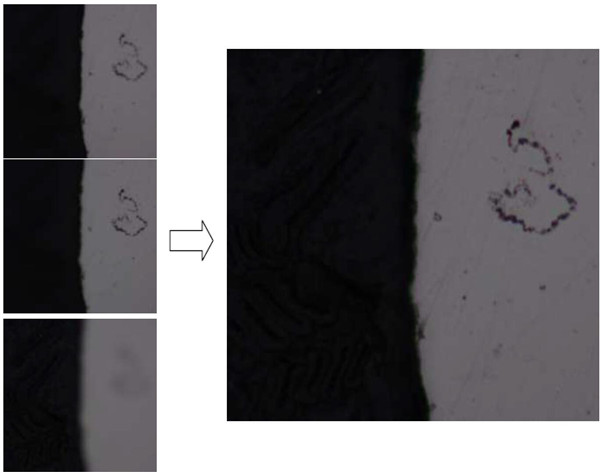

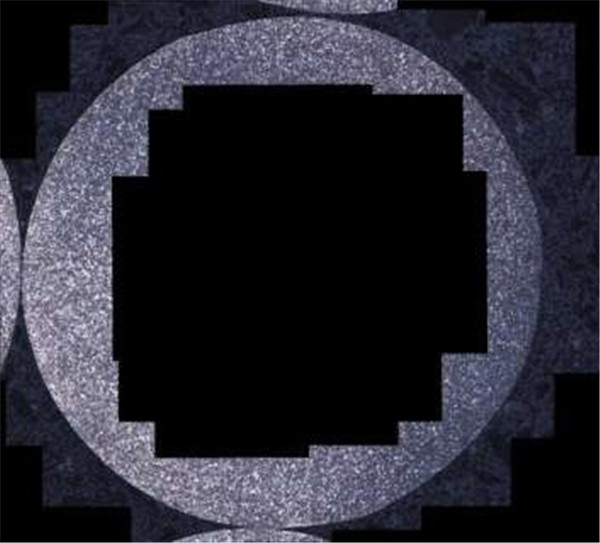

4、)Super Depth of Field Observation(EFI)

Thepowerful depth of field extension function (EFI) breaks through the depth offield of the optical microscope to obtain a clear view of the full field ofview; it perfectly solves the problem of taking pictures at high wire edges.

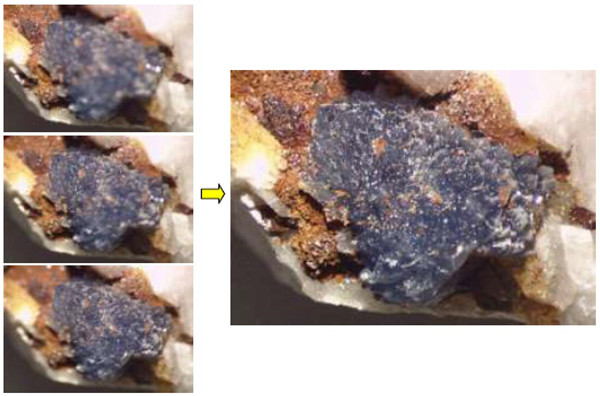

5、VolumeOffset Correction Depth of Field Observation (OffsetEFI)

For thespecial optical path of the stereoscopic mirror, the system automaticallycorrects the offset phenomenon in the stereo imaging to ensure the best effectof the depth of field expansion;

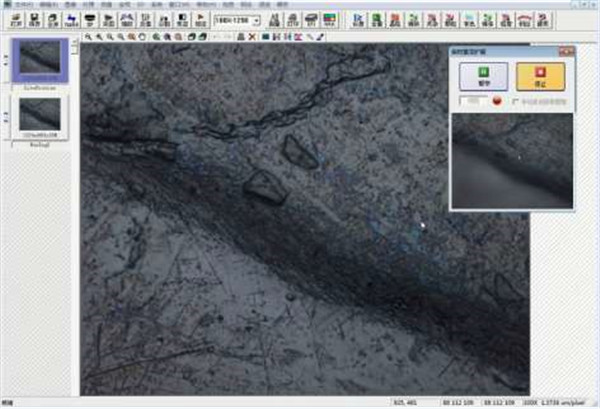

6、Real-timedepth of field extension (LiveEFI)

Intelligentreal-time depth of field extension (LiveEFI), perfect operating experience;only need to adjust the focal length, the system automatically records clearareas, automatically achieve super depth of field photography.

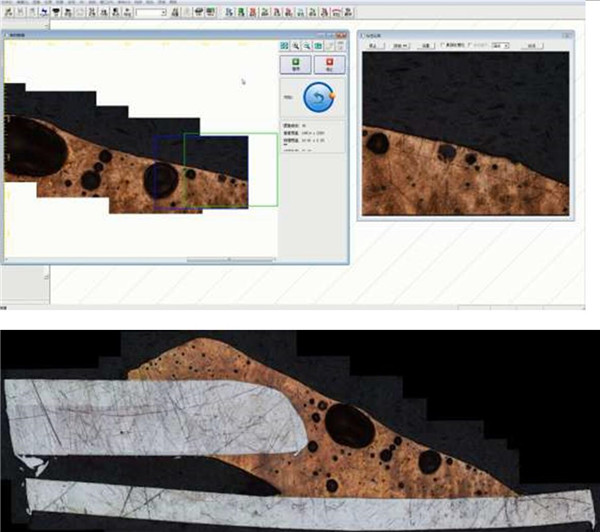

7、Large Field of View ImageAcquisition (MIA)

Theautomatic image stitching function (MIA) expands the field of view of themicroscope to obtain a smooth and over-large image of the field of view; it canbe used for high-resolution steel wire edge panoramas, defect analysis andmore.

8、Real-time imagestitching (LiveMIA)

Intelligentreal-time image stitching (LiveMIA), perfect operating experience, breaking thehorizon limit. As long as the stage is moved, the system automatically recordsthe scanned area and automatically takes a large field of view image withouttaking a picture.

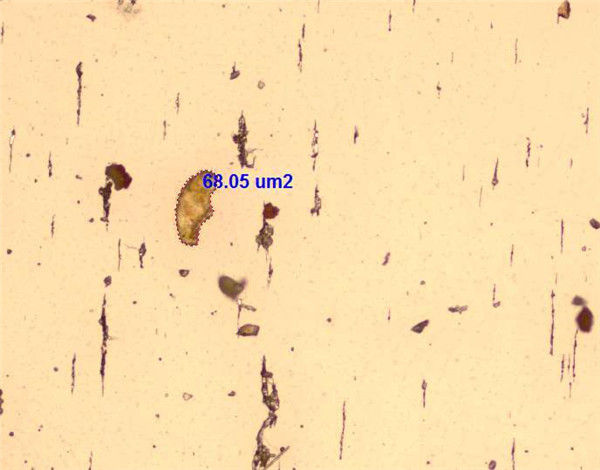

9、Target particle automatic edgefinding (ATE)

Automatically find particle boundaries basedon color differences;

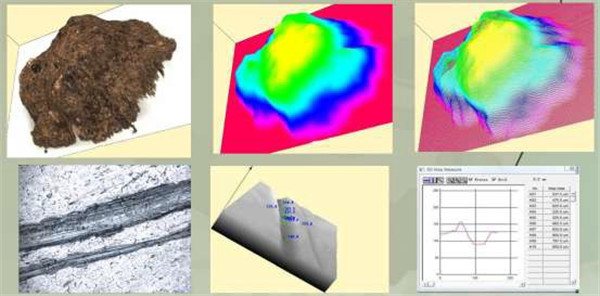

10、3D surface topography and 3Dmeasurement (3D)

3Dsurface topography, surface detail, etc. (3D Surface); plus the AUTOZ modulefor 3D Measure. Such as: measuring the groove depth in 3D mode;

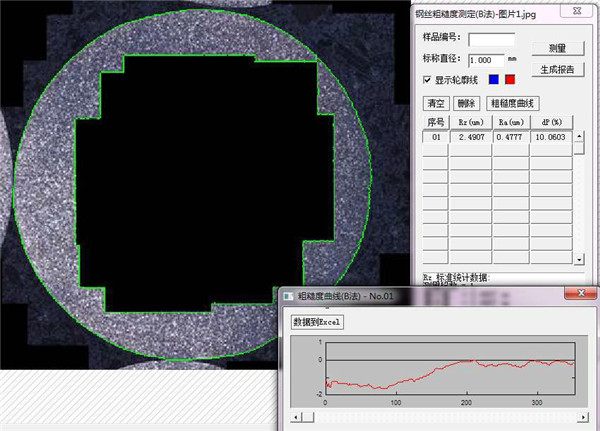

11、Professional wire roughnessanalysis algorithm

Designedfor Bekaert's special wire roughness analysis method; high-precision roughnesscalculation method, which automatically fits the curvature radius of thecurrent arc to obtain more accurate roughness. At the same time, multipleparameters such as Ra, Rz, and dp% are calculated. Supports advanced functionssuch as multi-segment arc measurement statistics, batch extraction, andautomatic morphology.

12、Roughness curve display

It canbe used to observe the roughness curve of the specified range in detail, whichis more intuitive and accurate.

13、Support rotary table measurementand conventional table splicing measurement

Supportmulti-segment arc measurement of the rotating table, and support theconventional table to splicing the entire wire surface for measurement. Thewhole picture measurement can reflect the appearance of the whole wire, whichis more intuitive and accurate.

14、Professional wire roughnessreport

A reportformat tailored specifically for wire roughness testing, with illustrations andtexts, allows you to view a complete analysis of the wire section. At the sametime, professional statistical data is output, including curvature diameter,Rz, Ra, dp% and other parameters.